Scientists 3D-Printed High-Dollar Wagyu Beef… Sorta

Scientists at Osaka University successfully 3D printed a marbled piece of Wagyu Beef. While better for cows, is it better for the environment?

You Are Reading :Scientists 3DPrinted HighDollar Wagyu Beef Sorta

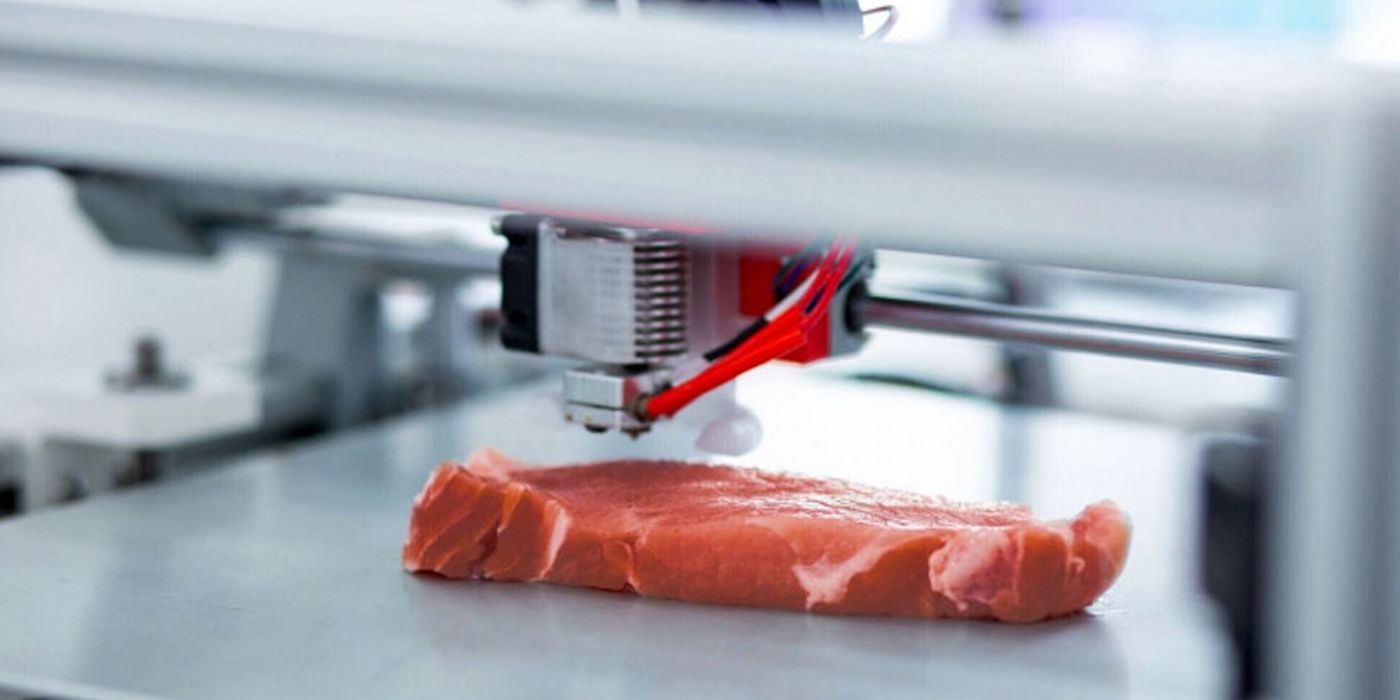

Scientists at Osaka University have successfully 3D printed a piece of wagyu beef-like meat, some of the most expensive meat in the world. 3D printing and meat have had a storied history. 3D printing food was first conceptualized in the mid-2000s at Cornell University by a group of students who produced cheese, cookie dough, and chocolate. These foods were selected as they were malleable, simple, and easy to melt down and load into a printer. Fast forward to 2018 and Spanish startup Novasteak became the first commercial producer of meat-free 3D printed steaks.

The process to create 3D-printed meat is a simple one. Using plant-based extracts the slab of ‘meat’ is broken down into three sections: muscle, fat, and blood lined in strips. After being cooled they are then pureed and then fed into a 3D printer. Software on the 3D printer then determines the optimum places to put the blood, muscle, and fat when producing the meat. After the printing is finished the meat is then pressed to adhere all the layers together, after which it can be chopped, grilled, and eaten. Manufacturing time varies depending on the size of the cut, with even the smallest cutlet taking several hours to reach completion.

What makes Osaka University’s efforts unique is the marbling, which is Wagyu beef’s signature draw, adding to its rich flavor and distinctive texture. The scientists were able to adjust the fat content of the beef to make it more similar to a fatty cut of steak. This was achieved by using two types of stem cells: bovine satellite cells, and adipose-derived stem cells. Under the correct lab conditions, these cells develop into every type of cell needed to produce cultured meat. The fibers produced from this method are then arranged in 3D similar to historical methods of meat 3D production. To make the wagyu beef cut the scientists used histological blueprints of the composition of the expensive cut. Such research opens the door to having specific cuts of meat 3D printed.

Good To Taste, Good For The Planet

The research paper states that the experiment was carried out following ethical, environmental, economic, and public health concerns with the cultivation of meat. Indeed, it is clear the benefits of producing meat in a lab via 3D printers now that fat positioning can be controlled to make it taste truly authentic. The environmental benefits speak for themselves, as agriculture is responsible for 18% of greenhouse gases worldwide. Ethically it makes sense as no cow would have to die in the production of good-tasting beef. While these early meat-printing efforts are costly, as the technology advances it may reach a point where high-quality meats would potentially cost less than rearing cattle.

The only thing holding this research back is the time it takes to 3D print a cut of high-quality meat. With it taking hours to print even the most petite cuts, it’s not the most appetizing process to watch. But once 3D printers become more efficient at producing high-quality constructs, we could see the face of modern agriculture change entirely as 3D printers become more lucrative than livestock thanks to scientists.

Link Source : https://screenrant.com/3d-printed-wagyu-beef-japan/